In today’s advanced technological landscape, cleanrooms […]

In today’s advanced technological landscape, cleanrooms have become essential for industries that require highly controlled environments. From pharmaceuticals and biotechnology to electronics and aerospace manufacturing, the need for contamination-free spaces is paramount. At the heart of these specialized facilities lies a critical component: clean room panels. These panels play a crucial role in maintaining the stringent environmental conditions necessary for sensitive processes.

The primary function of clean room panels is to create a barrier against dust, microbes, and other contaminants while facilitating temperature and humidity control. Their design incorporates features like smooth surfaces, rounded corners, and minimal joints to prevent the buildup of particles and simplify cleaning procedures.

Contamination Control : In industries where even microscopic particles can compromise product quality, clean room panels help maintain ultra-low levels of contamination by creating a sealed environment.

Energy Efficiency : With superior insulation properties, clean room panels contribute to energy savings by reducing heating, ventilation, and air conditioning (HVAC) system loads.

Quick Installation : Modular designs allow for rapid assembly and disassembly, enabling flexible configurations tailored to specific operational requirements.

Durability and Maintenance : High-quality materials ensure longevity, while the smooth finish resists corrosion and wear, making them ideal for long-term use.

Compliance with Standards : Clean room panels meet international standards such as ISO 14644-1, ensuring adherence to regulatory guidelines across various industries.

Types of Clean Room Panels

Several types of clean room panels cater to diverse needs:

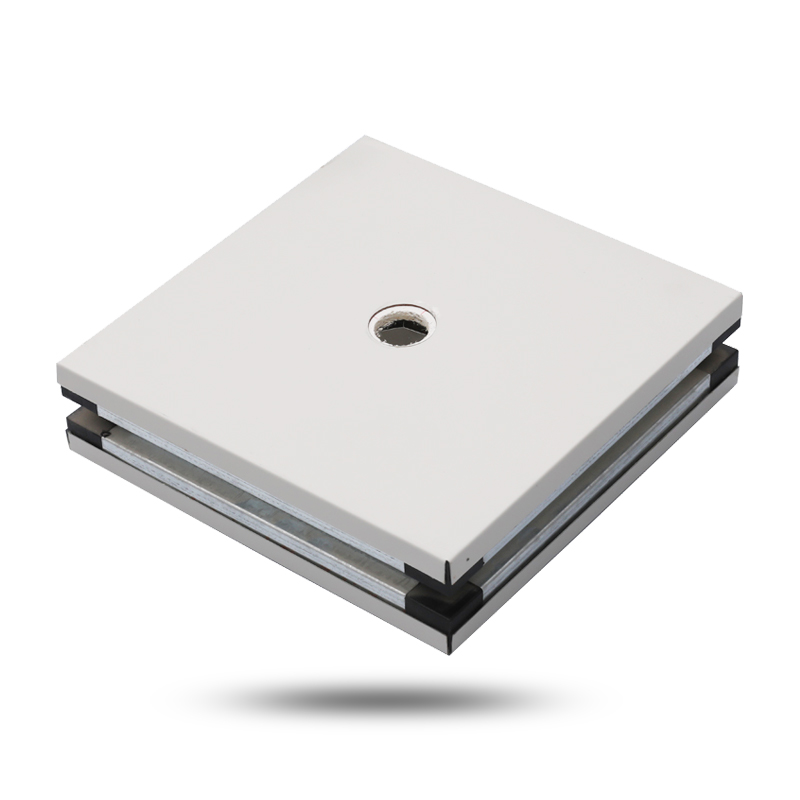

Sandwich Panels : Composed of two outer layers sandwiching a core material (e.g., PU, EPS, or mineral wool), these panels offer exceptional strength, insulation, and fire resistance.

Metal Clad Panels : Featuring metal skins on both sides, these panels are highly durable and suitable for environments requiring frequent washdowns or exposure to chemicals.

Glass Reinforced Plastic (GRP) Panels : Lightweight yet robust, GRP panels resist moisture and chemical damage, making them ideal for wet areas.

Hollow Core Panels : These lightweight panels are cost-effective and commonly used in less demanding applications.

Applications Across Industries

Clean room panels find widespread use in numerous sectors:

Pharmaceuticals and Biotechnology : Ensuring sterility during drug production and research activities.

Electronics Manufacturing : Protecting delicate components from dust and static electricity during assembly.

Food Processing : Maintaining hygienic conditions to comply with food safety regulations.

Aerospace and Defense : Supporting precision engineering tasks where contamination could jeopardize performance.

Medical Devices : Providing sterile environments for the development and testing of medical equipment.

Challenges and Future Prospects

Despite their advantages, clean room panels face certain challenges. For instance, achieving perfect airtightness and minimizing panel seams remains a technical hurdle. Additionally, balancing cost-effectiveness with high-performance characteristics can be difficult for manufacturers.

Looking ahead, advancements in material science and manufacturing techniques promise to enhance the capabilities of clean room panels. Innovations such as antimicrobial coatings, improved thermal efficiency, and enhanced sustainability through recyclable materials will likely shape the next generation of cleanroom solutions.

Moreover, smart technologies integrated into clean room panels—such as sensors for real-time monitoring of environmental parameters—could revolutionize how cleanrooms operate. These innovations would not only improve efficiency but also reduce human error in maintaining optimal conditions.

Clean room panels are indispensable in the construction of modern cleanrooms, offering unparalleled benefits in terms of contamination control, energy efficiency, and adaptability. As industries continue to evolve, so too will the demand for advanced clean room solutions. By addressing current challenges and embracing emerging technologies, clean room panels will undoubtedly remainat the forefront of creating safe, efficient, and compliant working environments for years to come.

Our new models offer superb design;competitive prices and their new features give them distinct advantages over similar products from other manufacturers.