In many high-tech and sensitive industries, such as pha […]

In many high-tech and sensitive industries, such as pharmaceuticals, electronic manufacturing, and medical device production, cleanrooms are indispensable facilities. The production environment requirements of these industries are extremely strict, and the control of particles, bacteria, humidity, and temperature in the air must meet specific standards. Cleanroom panels, as an important part of cleanroom construction, play a vital role.

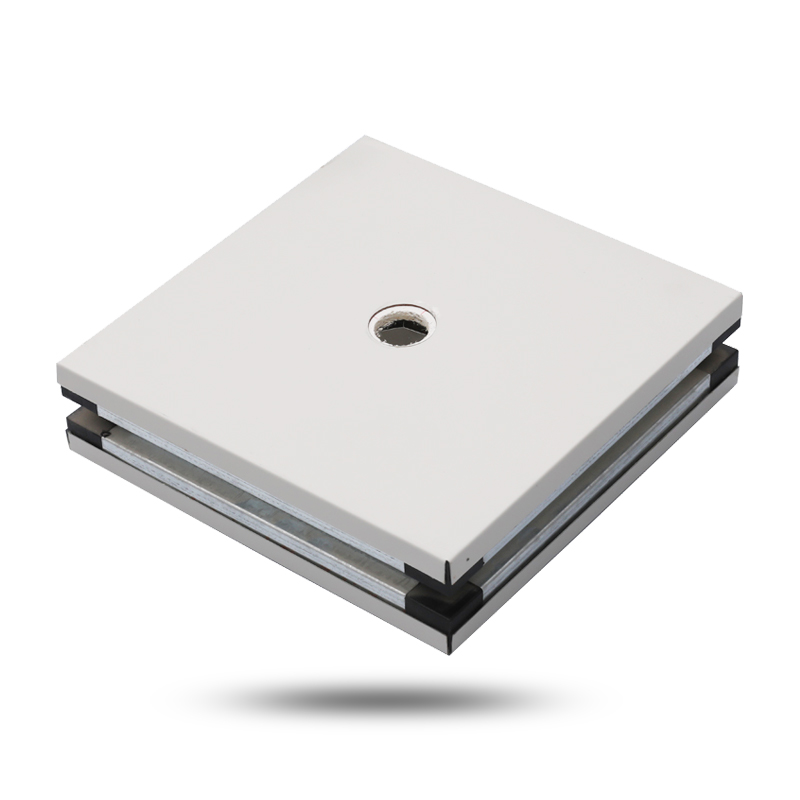

Cleanroom panels, also known as purification panels, are a type of building material designed specifically for clean environments. Compared with traditional building materials, cleanroom panels have unique characteristics that can meet the high standards of cleanroom hygiene, safety, and environmental control.

Cleanroom panels are usually made of metal plates, stainless steel, or special coating materials, and have a very smooth surface that can effectively prevent the accumulation of dust, bacteria, and other contaminants. This smooth surface is not only easy to clean, but also reduces the adhesion of particles, ensuring the air quality in the cleanroom.

Because the environment in the cleanroom requires strict control of the presence of microorganisms, cleanroom panels usually have an antibacterial coating. This coating can inhibit the growth of bacteria and fungi, further reducing the risk of contamination.

Another key feature of cleanroom panels is fire resistance. To ensure safety in cleanrooms, panel materials are usually selected with flame-retardant properties, which can provide longer escape and control time in the event of a fire.

Cleanrooms need to maintain a strictly controlled air pressure environment to prevent the infiltration of outside air. When designing cleanroom panels, full consideration is given to their airtightness to ensure that there are no gaps in the seams and joints of the panels to prevent air leakage.

In some cleanrooms, corrosive chemicals may be used. Cleanroom panels must be able to resist the erosion of these chemicals and maintain their structural and surface integrity.

Cleanroom panels are widely used in cleanroom construction in multiple industries. Here are some of the main application scenarios:

In pharmaceutical production, especially in the production of sterile drugs, the cleanliness of the environment is extremely high. Cleanroom panels are used to construct walls, ceilings and floors to ensure the sterility of the production environment and prevent drugs from being contaminated.

The manufacturing process of semiconductors and electronic products has very strict requirements for the control of particles. Cleanroom panels provide a dust-free and stable space in these production environments, reducing product defect rates and improving production efficiency.

In some high-demand food processing environments, cleanroom panels are used to prevent food from being contaminated by the outside world during processing, ensuring product safety and quality.

The production of medical devices also has stringent requirements for cleanliness. Cleanroom panels help maintain the cleanliness of the production environment, ensure the sterility of the equipment, and avoid the risk of patient infection.

Many scientific research facilities require highly controlled environments, especially in the fields of microbiology, cell culture, and genetic engineering. Cleanroom panels provide a stable environment for these laboratories to ensure the accuracy and reliability of experimental results.

The design and construction of cleanrooms must strictly follow industry standards and regulations, such as ISO 14644, GMP (Good Manufacturing Practice), etc. These standards specify requirements for cleanroom air quality, particulate matter concentration, temperature and humidity control, and cleanroom panels play a vital role in the implementation of these standards.

By selecting the right cleanroom panel material and design, it can be ensured that the air quality in the cleanroom meets the standard, the concentration of particles and microorganisms is reduced, and the requirements of production and scientific research are met. In addition, cleanroom panels must also be able to adapt to the cleaning and maintenance needs in the cleanroom to maintain long-term use effects and environmental stability.

Cleanroom panels are an indispensable building material in a high-standard clean environment. It not only has excellent surface smoothness, antibacterial properties, fire resistance and air tightness, but also plays a key role in various rigorous application scenarios. Whether in the pharmaceutical, electronic manufacturing or food processing industries, clean room panels help these fields maintain a clean and safe production environment. By deeply understanding the characteristics and applications of clean room panels, companies can better build clean rooms that meet standards and ensure product quality and production safety.

Our new models offer superb design;competitive prices and their new features give them distinct advantages over similar products from other manufacturers.