Cleanroom panels are special building materials used fo […]

Cleanroom panels are special building materials used for cleanroom walls and ceilings, mainly used to ensure indoor cleanliness and sealing. This panel has the characteristics of anti-static, easy to clean, and corrosion-resistant, and can effectively block the intrusion of external pollutants and prevent the accumulation of particles, dust and bacteria, thereby achieving the purpose of controlling air quality.

Cleanroom panels are usually installed on the walls and ceilings of cleanrooms to form a sealed space structure. By matching the air filtration system, air conditioning system, etc. in the cleanroom, the cleanroom panels can effectively maintain the high cleanliness of the room and meet the strict requirements of production and scientific research.

The core function of the cleanroom panel is to ensure the sealing of the room, thereby preventing the entry of pollutants. The joints generally use special sealing technology, such as sealing strips or silicone sealing, to ensure that tiny particles in the air do not enter the room through the gaps.

The surface of the cleanroom panel is usually smooth and bright, which makes cleaning and disinfection more convenient. Some advanced cleanroom panels also use antibacterial coatings to reduce the growth of bacteria and meet the requirements of high hygiene standards.

In order to meet the use requirements in different environments, clean room panels need to have good fire resistance to ensure that the fire can be prevented from spreading when a fire occurs. In addition, some panel materials are corrosion-resistant and can resist the erosion of chemicals, making them suitable for special environments such as the pharmaceutical and chemical industries.

Clean room panels are generally made of lightweight materials, which are easy to install and replace, while having high strength and stability, and can withstand the vibration and pressure changes of equipment in the clean room.

Depending on the cleanliness requirements and application scenarios of the clean room, the material selection of clean room panels is also different. Common clean room panel materials include:

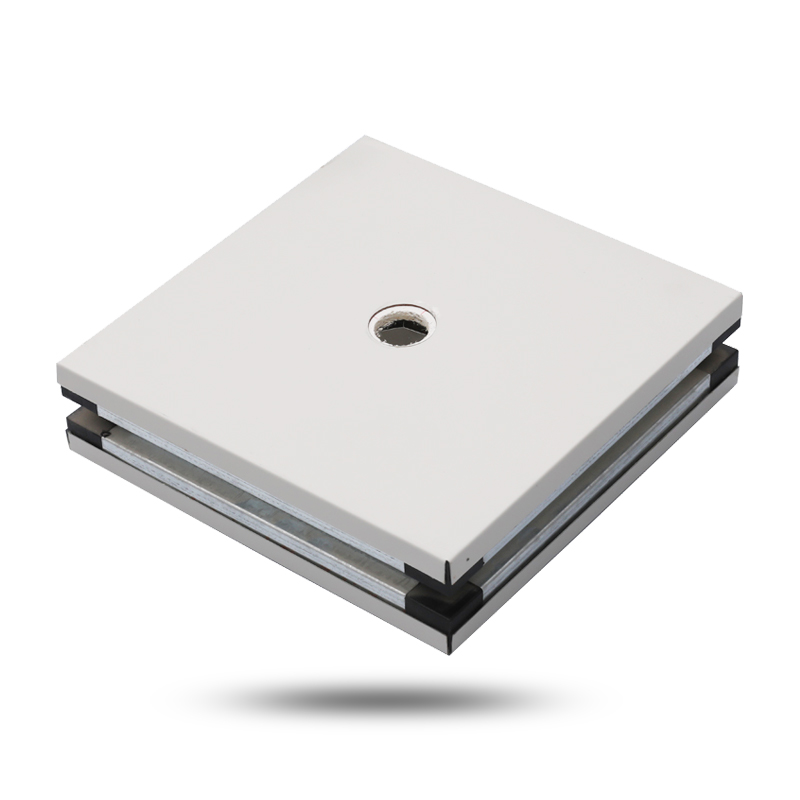

Color steel plate clean room panel is one of the most commonly used types. The color steel plate with surface coating has good anti-corrosion and dust-proof properties. It is light in weight and relatively economical in price, making it the first choice for most clean room projects.

For clean rooms with higher requirements, such as biopharmaceuticals and semiconductor industries, stainless steel panels are usually used. This type of panel has extremely high corrosion resistance and mechanical strength, and can resist corrosion from cleaning and disinfectants. In addition, the smooth surface of the stainless steel panel is easy to clean and can effectively inhibit the growth of microorganisms.

Aluminum honeycomb panels are often used in cleanroom walls and ceilings because of their stable structure, light weight and good pressure resistance. The honeycomb structure inside provides high strength and impact resistance, while the aluminum on the outer layer of the panel can be treated with anti-corrosion to adapt to different clean environment requirements.

These inorganic cleanroom panels have excellent fire and moisture resistance and are often used in cleanroom environments that require special fire protection requirements.

The semiconductor industry has extremely high requirements for the cleanliness of the production environment, and any tiny particles or static interference may have a serious impact on product quality. Cleanroom panels can ensure efficient isolation and protection in such a high-demand environment, ensuring that the number of particles in the air meets the specified standards.

The production environment in the pharmaceutical and biotechnology fields needs to be kept sterile to prevent the intrusion of contaminants. The antibacterial and easy-to-clean properties of cleanroom panels can help maintain a sterile environment and ensure the quality and safety of drugs.

In the food industry, cleanroom panels are used to prevent contamination during food production. Highly sealed panels help keep the environment clean, thereby improving food hygiene standards and extending the shelf life of food.

The aerospace field involves high-precision manufacturing processes, and the construction of clean rooms is crucial to ensuring equipment performance and product quality. The high sealing and fire resistance of clean room panels are widely used in this field.

With the continuous development of clean technology, clean room panels are also constantly improving in materials, structures and installation processes. Future development trends mainly include the following aspects:

In order to meet more stringent cleanliness and environmental requirements, the materials of clean room panels will develop in the direction of lighter weight, higher strength and more corrosion resistance. The application of nanomaterials and composite materials will further enhance the performance of clean room panels.

Modular clean room panel design will make installation easier and faster, reducing construction time and cost. The development of rapid installation technology can greatly improve the efficiency of clean room construction and meet the needs of rapid expansion.

With the popularization of Internet of Things technology, smart clean room panels may integrate sensors and monitoring equipment to achieve real-time monitoring and adjustment of environmental parameters such as cleanliness, temperature and humidity.

As a key building material in clean room construction, clean room panels are widely used in high-precision industries such as electronics, medicine, food, and aviation. Its high sealing, easy cleaning and diverse material selection make clean room panels play an irreplaceable role in ensuring the cleanliness of the production environment. With the continuous advancement of material technology and installation technology, clean room panels will become more efficient and intelligent in the future, further promoting the development and application of clean technology.

Our new models offer superb design;competitive prices and their new features give them distinct advantages over similar products from other manufacturers.