In modern industry, medical treatment, pharmaceuticals, […]

In modern industry, medical treatment, pharmaceuticals, scientific research and other fields, cleanrooms have become important facilities for maintaining high-standard production and research environments. In these cleanrooms, cleanroom panels play an indispensable role. This article will explore in depth the role, type, selection and installation points of cleanroom panels to help readers better understand their importance in cleanroom construction.

Cleanroom panels are one of the core materials for building cleanroom environments, and their main function is to maintain the cleanliness of the indoor environment. Specifically, cleanroom panels ensure a clean environment in the following ways:

Cleanroom panels have a high degree of sealing, which can effectively prevent external pollutants from entering the cleanroom and ensure the stability of the indoor environment.

The surface of cleanroom panels is usually designed to be smooth and seamless to avoid the retention of dust and bacteria, making the cleaning process more efficient and simple.

Cleanroom panels need to be resistant to chemical corrosion to adapt to various disinfectants and chemicals used in different cleanroom environments.

In fields such as electronics and pharmaceuticals, cleanroom panels also need to have anti-static properties to prevent product quality problems or production accidents caused by static electricity.

According to different application needs and environmental requirements, there are many types of cleanroom panels to choose from. The common ones are as follows:

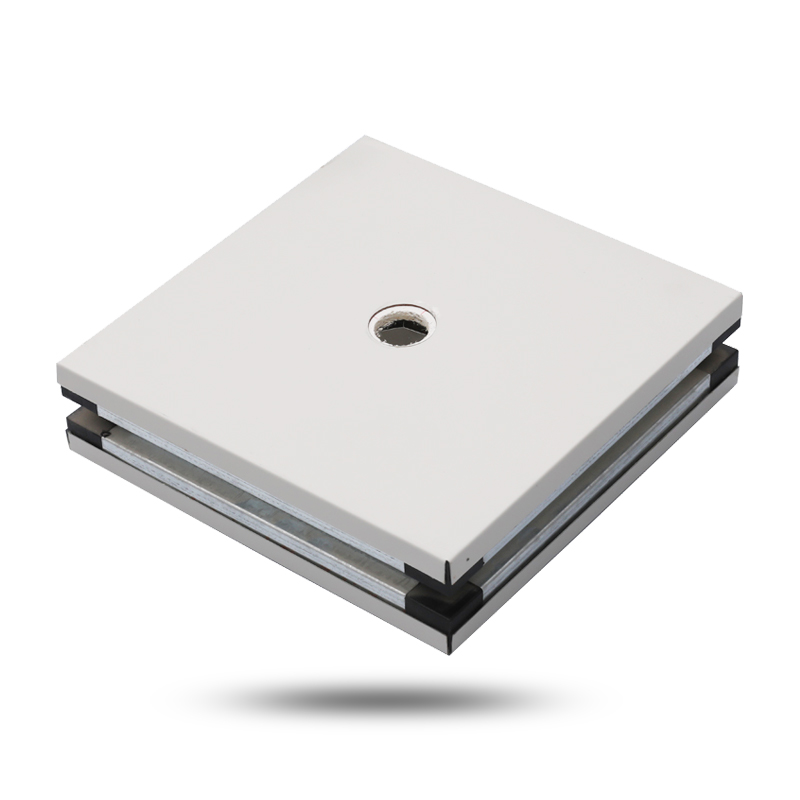

Colored steel panel is one of the most commonly used materials in cleanrooms. It is composed of high-quality galvanized steel plate and coating, and has good fire, moisture and corrosion resistance. Its lightweight structure makes it easy to install and suitable for all types of cleanrooms.

This panel is composed of aluminum plate and honeycomb core material. It has extremely high rigidity and good flatness. It is light, corrosion-resistant and easy to clean. It is often used in cleanroom environments with high requirements.

Stainless steel panels are suitable for medical, pharmaceutical and other environments with extremely high hygiene requirements due to their excellent corrosion resistance and high strength. Its surface is smooth and easy to clean, and it can withstand frequent disinfection.

Glass magnesium board panel is a new type of environmentally friendly material with fire, moisture and antibacterial properties. Its high strength and durability make it an ideal choice for many high-end cleanrooms.

Choosing the right cleanroom panel is essential to ensure the functionality and long-term stability of the cleanroom. Here are a few key considerations:

Choose a panel material that meets the standard according to the clean level required for the cleanroom (such as ISO 5, ISO 7, etc.). Environments with high cleanliness levels usually require panels with higher sealing and anti-static properties.

Consider the temperature, humidity, and chemical types in the cleanroom, and choose the type of panel that adapts to these environmental conditions. For example, in a high humidity environment, a panel with moisture-proof properties should be selected.

Although high-end panel materials such as stainless steel and aluminum honeycomb panels are more expensive, their excellent durability and performance make them more cost-effective in long-term use. Make the right choice based on the project budget and life cycle.

The ease of installation and maintenance of the panel is also a factor to consider when choosing. Panels that are easy to install and maintain can not only reduce the initial installation cost, but also reduce the maintenance workload in the future.

In order to ensure the sealing and cleanliness of the cleanroom, the installation process of the panel must be carried out strictly in accordance with the standards. Here are some key installation points:

Before installation, the cleanroom needs to be accurately measured and the panels need to be accurately cut according to actual needs to ensure seamless connection between panels.

At the joints and edges of the panels, they need to be fully sealed, using professional sealants or sealing strips to prevent any contaminants from entering the cleanroom through the gaps.

The panel needs to be fixed firmly to prevent displacement or loosening due to external forces during use.

After installation, sealing tests and cleanliness checks are required to ensure that the panel installation meets the requirements of the clean room.

As an important part of clean room construction, the selection and installation of clean room panels directly affect the overall performance and service life of the clean room. Whether in the fields of medical, pharmaceutical, electronic or scientific research, choosing the right clean room panel and strictly following the installation specifications can ensure the efficient operation and safety of the clean room environment. With the continuous advancement of technology, the clean room panels of the future will be more diversified and high-performance, providing better clean environment guarantees for all walks of life.

Our new models offer superb design;competitive prices and their new features give them distinct advantages over similar products from other manufacturers.