With the rapid development of science and technology, c […]

With the rapid development of science and technology, cleanrooms are becoming increasingly important in high-tech industries such as semiconductors, pharmaceuticals, biotechnology, electronic manufacturing, and aerospace. These industries have extremely high requirements for the cleanliness of the environment, and any tiny contamination may have a serious impact on the quality of the product and the production process. Clean room panels, as an important part of cleanrooms, play a vital role.

The main function of cleanroom panels is to create a controlled environment to prevent pollutants from entering the clean area, ensuring the cleanliness of the air and the stability of the indoor environment. The air quality of the cleanroom is strictly controlled, and pollutants such as dust particles, bacteria, and chemical gases in the air must be kept at an extremely low level. The panels reduce the penetration and accumulation of pollutants through sealing structures, antibacterial coatings, and corrosion-resistant materials. In addition, cleanroom panels also have functions such as heat insulation, sound insulation, and fire prevention, which further improve the safety and environmental control capabilities of cleanrooms.

Cleanroom panels are classified in many ways according to different application requirements and material properties:

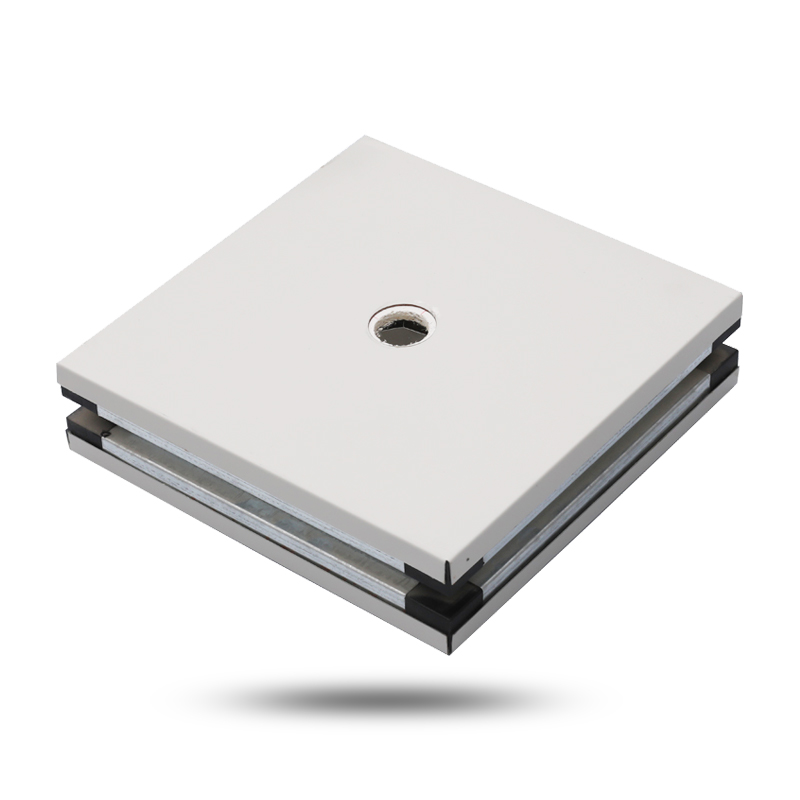

Colored steel sandwich panels are one of the commonly used materials in cleanrooms. They are composed of double-layer colored steel plates and sandwich materials (such as polyurethane, glass wool, rock wool, etc.). This panel is lightweight, high-strength, and has good thermal and sound insulation properties. It is widely used in clean rooms that require high strength and impact resistance.

Stainless steel panels are highly corrosion-resistant and can withstand chemical cleaning and disinfection in clean rooms. Its smooth surface is easy to clean and is suitable for use in the medical and pharmaceutical industries that require high antibacterial properties.

Aluminum honeycomb panels are lightweight, rigid, and have good fire resistance and corrosion resistance. Its honeycomb structure can increase the strength of the panel while reducing the weight of the material, making it an ideal choice for high-end clean room applications.

Glass magnesium board is an environmentally friendly material that is fireproof, high temperature resistant, corrosion resistant, antibacterial and moisture-proof. It is suitable for clean rooms that require high fire resistance and antibacterial properties.

Clean room panels are widely used in multiple high-tech and high-precision industries:

The semiconductor and electronic manufacturing processes have extremely strict requirements on particulate matter in the air. Clean room panels can effectively control the number of particles in the air and prevent fine dust from damaging precision electronic components.

Drug production and biotechnology experiments require strict control of microbial and particle contamination. Cleanroom panels can provide a sterile environment that meets GMP (Good Manufacturing Practice) standards to ensure product purity and quality.

In medical places such as operating rooms and sterile wards, cleanroom panels can be used to control bacteria and viruses in the air, reduce the risk of postoperative infection, and provide a safe medical environment.

The production process of food and beverages needs to be carried out in a sterile environment to prevent bacterial contamination. Cleanroom panels can maintain the cleanliness of the workshop and ensure the safety and quality of food.

The component manufacturing and assembly process in the aerospace industry needs to be carried out in a highly clean environment. Cleanroom panels can prevent the impact of external pollution on precision components and ensure the high quality of products.

The installation process of cleanroom panels needs to be carried out in strict accordance with the design specifications of the cleanroom to ensure the sealing of each joint and the flatness of the panel. In addition, the air flow path in the cleanroom needs to be considered during installation to avoid the panel from hindering the circulation of air. At the same time, the maintenance of cleanroom panels is also very critical. Regular cleaning and disinfection are important measures to maintain cleanliness. Choose suitable cleaners and disinfectants, avoid using chemicals that are harmful to panel materials, and extend the service life of the panels.

With the advancement of technology and the increasing demand for clean environment, the future development of clean room panels will show the following trends:

With the enhancement of environmental awareness, the materials of clean room panels will pay more attention to sustainability and environmental friendliness. In the future, environmentally friendly materials such as recyclable metal alloys, plant-based materials, etc. will be more widely used in clean room panels.

Intelligent panels will integrate sensors and control systems, which can automatically detect parameters such as air quality, temperature, humidity, and make real-time adjustments to environmental changes. This automated system can improve the operating efficiency and management level of clean rooms.

Future clean room panels will be more multifunctional, integrating multiple functions such as fire prevention, antibacterial, sound insulation and heat insulation to meet the special needs of different clean rooms. In addition, the application of nano-coating technology will also improve the antibacterial and anti-fouling properties of the panels.

Clean room panels play an indispensable role in modern high-tech industries, and their multiple functions and wide applications make them a key material for clean room construction. With the continuous advancement of technology and the growth of market demand, the materials and designs of clean room panels will continue to develop to provide more efficient, environmentally friendly and intelligent solutions for clean rooms. In the future, cleanroom panels will continue to play an important role in the construction and maintenance of dust-free environments, promoting the development and innovation of various industries.

Our new models offer superb design;competitive prices and their new features give them distinct advantages over similar products from other manufacturers.