Clean room panels are constructed with specific materia […]

Clean room panels are constructed with specific materials and design features to ensure both cleanliness and durability, essential for maintaining controlled environments. Here are key aspects of their construction:

Material Selection:

Clean room panels typically have a core material that provides structural integrity and insulation properties. Common core materials include rigid foam (such as polyurethane or polystyrene), mineral wool, or aluminum honeycomb.

The outer surfaces of clean room panels are usually made from materials that are easy to clean and resistant to microbial growth. This often includes materials like galvanized steel, stainless steel, aluminum, or high-pressure laminates (HPL).

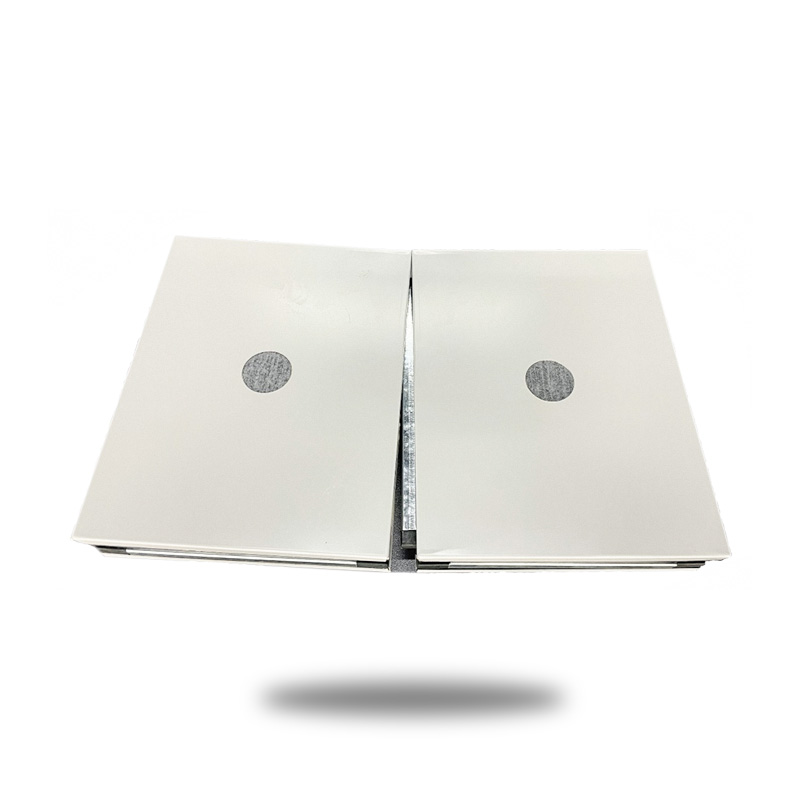

Seamless Construction:

Clean room panels are designed to have minimal joints and seams to reduce the potential for contamination and make cleaning easier. Where seams are necessary, they are sealed tightly to prevent particle ingress.

Smooth and Non-Porous Surfaces:

The surfaces of clean room panels are smooth and non-porous to prevent the accumulation of dust, particles, or microorganisms. This facilitates easier cleaning and maintenance.

Integrated Gaskets and Seals:

Clean room panels often feature integrated gaskets and seals around edges and joints to ensure airtightness and prevent leaks that could compromise the clean environment.

Antimicrobial Coatings or Treatments:

Some clean room panels may have antimicrobial coatings or treatments applied to their surfaces to inhibit the growth of bacteria or fungi, further enhancing cleanliness.

Fire Resistance and Safety:

Clean room panels are typically designed to meet fire safety regulations and may incorporate fire-resistant materials or coatings to ensure safety in the event of a fire.

Modularity and Compatibility:

Clean room panels are often modular in design, allowing for easy assembly, disassembly, and reconfiguration. They are engineered to integrate seamlessly with clean room HVAC systems, utilities, and other infrastructure.

By combining these construction techniques and materials, clean room panels provide a reliable barrier against contamination while offering durability and ease of maintenance, essential for maintaining stringent cleanliness standards in controlled environments such as pharmaceutical facilities, biotechnology labs, electronics manufacturing, and healthcare settings.

Our new models offer superb design;competitive prices and their new features give them distinct advantages over similar products from other manufacturers.