Sandwich panels typically consist of three main layers […]

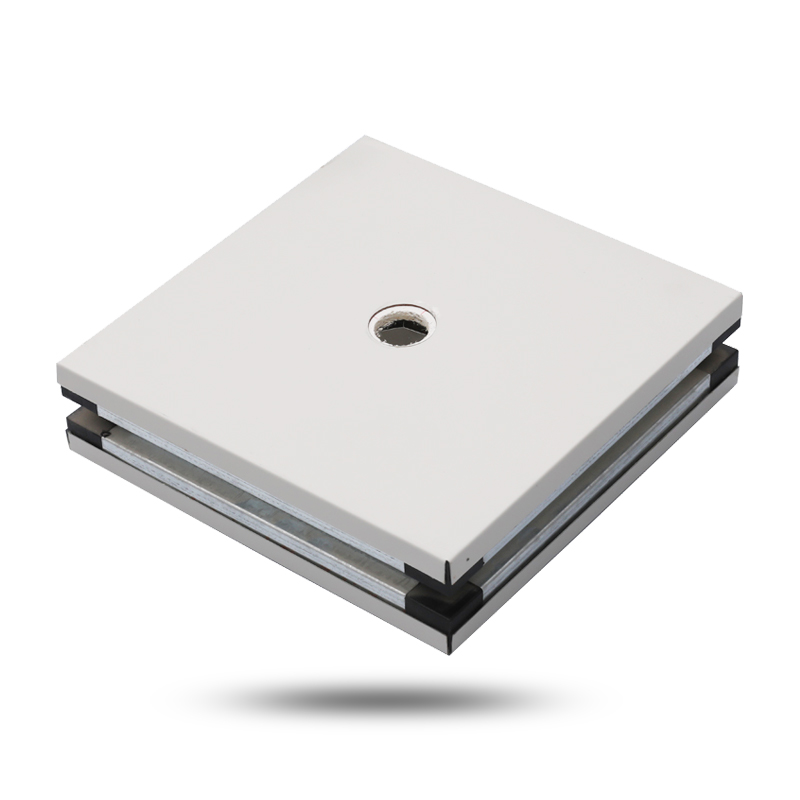

Sandwich panels typically consist of three main layers bonded together to form a single structural unit. Here's a typical construction and bonding process:

Outer Facings or Skins:

The outer layers, also known as facings or skins, are usually made from materials like metal (aluminum, steel), fiberglass, or composite materials.

These skins provide strength, durability, and weather resistance to the sandwich panel.

Core Material:

The core material is placed between the outer facings and plays a crucial role in providing insulation, structural integrity, and often contributes to the panel's overall stiffness.

Common core materials include:

Foam Cores: Expanded polystyrene (EPS), polyurethane (PU), polyisocyanurate (PIR), etc.

Honeycomb Cores: Aluminum, fiberglass, or aramid honeycomb structures.

Mineral Wool or Rock Wool: Provides excellent fire resistance and thermal insulation.

Bonding Process:

The layers are bonded together using adhesives or bonding agents specifically designed for the materials involved.

The bonding process is crucial to ensure the integrity and performance of the sandwich panel.

Depending on the application and materials used, additional methods like mechanical fasteners or welding may also be employed to reinforce the bond.

Manufacturing Techniques:

Sandwich panels are often manufactured using techniques such as:

Continuous Lamination: Where layers are bonded together continuously along a production line.

Vacuum Bonding: Ensures a strong, uniform bond between layers by removing air and ensuring even distribution of adhesive.

Press Bonding: Applying pressure and heat to bond layers together effectively.

Finishing and Customization:

After bonding, sandwich panels may undergo additional processes such as cutting, profiling, and finishing to meet specific size, shape, and aesthetic requirements.

Surface treatments may include coatings for corrosion resistance, paint for color customization, or laminates for additional protection.

The construction and bonding of sandwich panels are engineered to optimize strength, insulation, and other performance characteristics required for various applications in construction, transportation, and industrial sectors.

Our new models offer superb design;competitive prices and their new features give them distinct advantages over similar products from other manufacturers.