Clean room panels contribute to energy efficiency in co […]

Clean room panels contribute to energy efficiency in controlled environments by incorporating various design features and technologies that optimize energy usage while maintaining the required cleanliness levels. Here's how clean room panels contribute to energy efficiency:

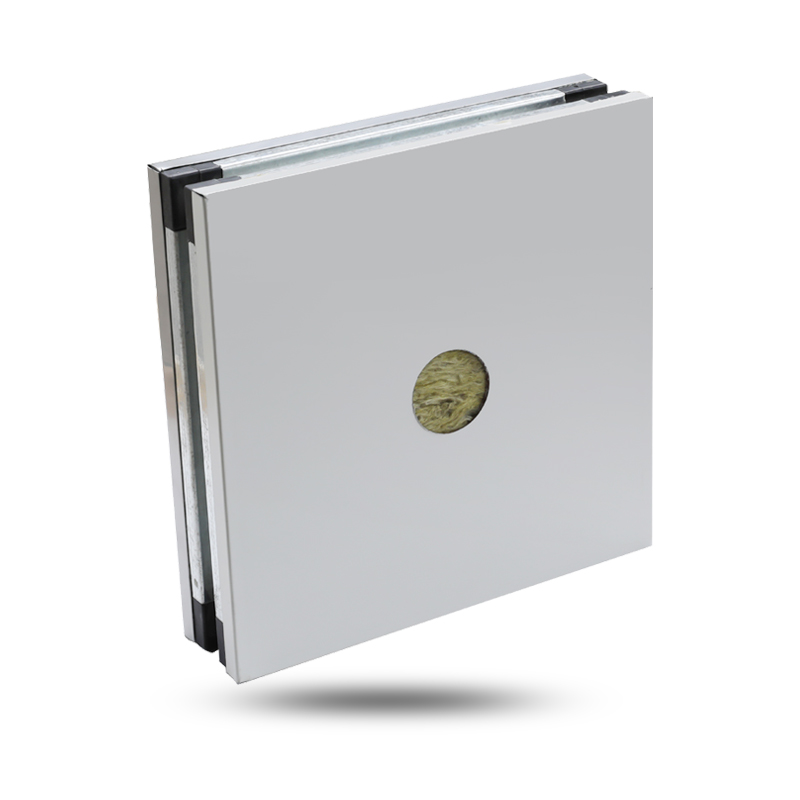

Insulation: Clean room panels are often constructed with high-quality insulation materials that help regulate temperature within the controlled environment. Effective insulation reduces heat transfer between the clean room and its surroundings, leading to energy savings by reducing the workload on HVAC systems.

Thermal Resistance: The materials used in clean room panels can have high thermal resistance values, which means they prevent heat from moving through the panels easily. This insulation property helps maintain a consistent temperature inside the clean room, reducing the need for excessive heating or cooling.

Sealing and Air Tightness: Clean room panels are designed with precise sealing mechanisms to minimize air leakage. This prevents the infiltration of unfiltered air from outside, reducing the load on heating and cooling systems required to maintain the desired temperature and cleanliness level.

Efficient HVAC Systems: Clean room panels are often integrated with efficient heating, ventilation, and air conditioning (HVAC) systems. These systems are designed to provide precise and controlled airflow, optimizing energy consumption by delivering conditioned air only where needed.

Airflow Control: Clean room panels allow for the integration of airflow control features such as laminar airflow systems. These systems ensure that filtered air is distributed evenly across the clean room space, minimizing energy waste by avoiding excessive air circulation.

Variable Air Volume (VAV) Systems: VAV systems adjust the amount of conditioned air delivered to the clean room based on real-time occupancy and cleanliness requirements. This dynamic approach optimizes energy usage by delivering air at levels necessary to maintain the specified conditions.

Energy-Efficient Lighting: Clean room panels can include integrated lighting systems with energy-efficient LED fixtures. Lighting controls and occupancy sensors ensure that lights are only active when needed, reducing unnecessary energy consumption.

Smart Building Management Systems: Clean room panels can be integrated into building management systems that monitor and control various environmental factors, such as temperature, humidity, and air quality. These systems optimize energy usage by adjusting settings based on real-time conditions.

Heat Recovery Systems: Some clean room panels can integrate heat recovery systems that capture and reuse waste heat from the ventilation or cooling processes. This further reduces the energy demand for heating.

Energy-Efficient Materials: Clean room panels often incorporate energy-efficient and sustainable materials that have lower environmental impacts and better thermal performance.

Optimized Design: Clean room panels are designed with energy efficiency in mind, including factors like placement of windows, doors, and equipment to minimize heat gain or loss.

Modularity: The modular nature of clean room panels allows for scalability and adaptability. If clean room requirements change, it's easier to modify the layout without significant disruption, minimizing the need for energy-intensive reconstruction.

By integrating these energy-efficient features and technologies, clean room panels help reduce overall energy consumption while still meeting the strict cleanliness and environmental requirements of controlled environments.

Our new models offer superb design;competitive prices and their new features give them distinct advantages over similar products from other manufacturers.