Clean room panels are designed to withstand wear and te […]

Clean room panels are designed to withstand wear and tear through their durable construction and often require minimal maintenance to ensure longevity. Here are key aspects of how they maintain durability and their maintenance requirements:

Durable Construction:

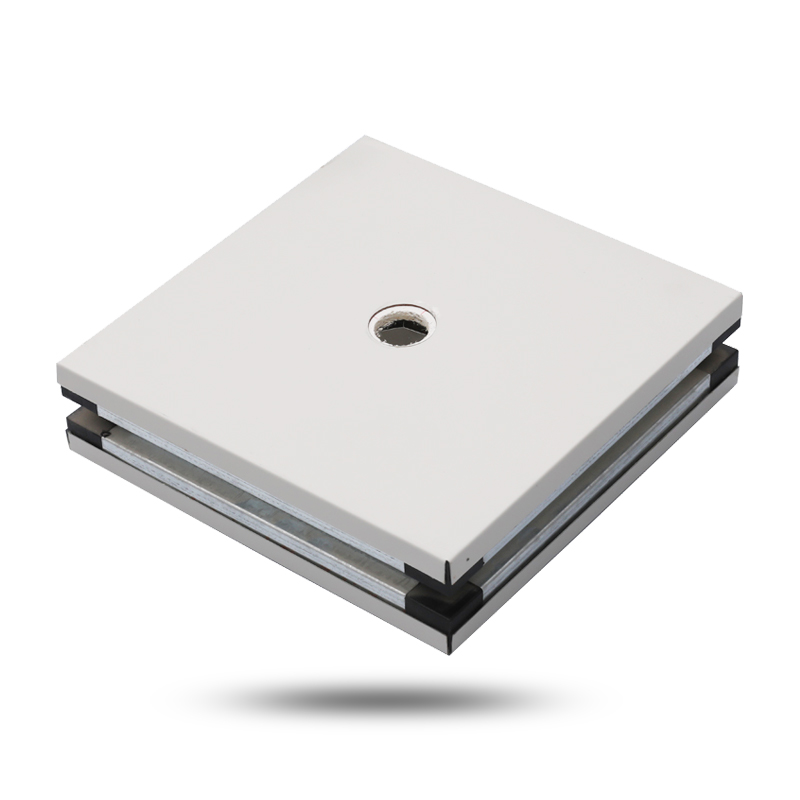

Clean room panels are typically constructed with robust materials such as galvanized steel, stainless steel, aluminum, or high-pressure laminates (HPL) for the outer surfaces. These materials are chosen for their strength, resistance to scratching, and ease of cleaning.

The core of clean room panels, often rigid foam or aluminum honeycomb, provides structural integrity and impact resistance, helping to prevent damage from impacts or heavy use.

Resistance to Environmental Factors:

Clean room panels are designed to withstand various environmental factors encountered in controlled environments, such as humidity, temperature fluctuations, and chemical exposure (depending on the specific panel materials and coatings used).

Maintenance Requirements:

Clean room panels typically require regular cleaning to maintain their appearance and performance. This involves removing dust, dirt, and any contaminants that could compromise cleanliness standards.

Use a mild soap or detergent solution with water to clean the panels. Avoid abrasive cleaners or harsh chemicals that could damage the surface or coatings.

Periodically inspect the seals and joints of clean room panels to ensure they remain intact and airtight. Repair any damaged seals promptly to prevent air leakage or contamination ingress.

Take precautions to avoid impact damage to clean room panels, as dents or punctures can compromise their integrity and cleanliness.

Professional Maintenance:

Consider periodic professional inspections and maintenance, especially for large or critical clean room installations. Professionals can identify potential issues early and perform specialized cleaning or repairs as needed.

Lifespan Expectancy:

Clean room panels are designed for long-term durability and can typically last for many years with proper maintenance. The lifespan can vary based on usage, environmental conditions, and maintenance practices.

By following these maintenance practices and ensuring proper handling, clean room panels can maintain their performance, cleanliness, and durability over their operational lifespan, contributing to the efficiency and reliability of controlled environments in industries such as pharmaceuticals, biotechnology, electronics, and healthcare.

Our new models offer superb design;competitive prices and their new features give them distinct advantages over similar products from other manufacturers.