In industries where maintaining a sterile and controlle […]

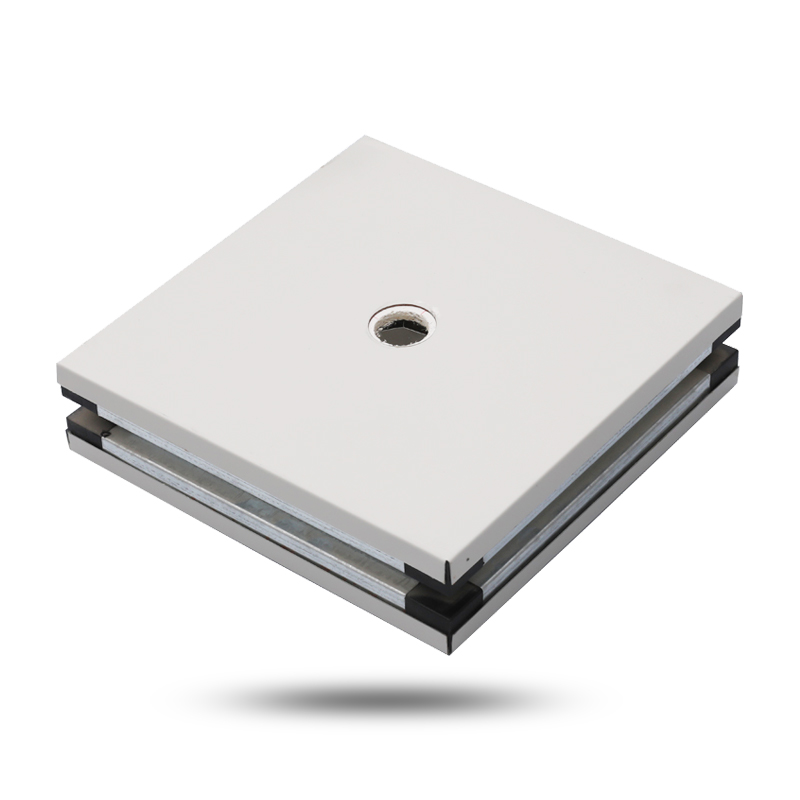

In industries where maintaining a sterile and controlled environment is crucial, such as pharmaceuticals, electronics, and biotechnology, the construction of clean rooms is of paramount importance. One essential component in the design and construction of these specialized spaces is the clean room sandwich panel. These panels are designed to meet the stringent requirements for cleanliness, temperature regulation, and structural integrity in environments where contaminants must be minimized or completely eliminated.

These panels are specially engineered to provide a combination of thermal insulation, structural strength, and resistance to contamination. Their smooth, non-porous surface makes them easy to clean and maintain, which is critical for environments where hygiene and cleanliness are paramount.

The core material of sandwich panels offers high thermal insulation, helping to maintain consistent temperatures within the clean room. This feature is essential for processes that are sensitive to temperature fluctuations.

The smooth, non-porous surface of the panels prevents the accumulation of dust, bacteria, and other contaminants. It also makes it easier to clean and sterilize the surfaces, ensuring that the environment remains free of pollutants.

Despite their insulating core, clean room sandwich panels are lightweight, which makes them easier to handle and install. At the same time, the outer layers provide structural strength, ensuring the panels can withstand mechanical stress and external pressures.

Many clean room sandwich panels are designed with fire-resistant properties to comply with safety regulations. This feature helps reduce the risk of fire hazards in controlled environments, which is especially important in industries like pharmaceuticals and electronics manufacturing.

Clean room sandwich panels can be customized to meet the specific requirements of a project. This includes variations in thickness, insulation material, and surface finishes, allowing for optimal performance based on the application.

Clean room sandwich panels help to maintain a controlled environment by minimizing the risk of contamination. Their non-porous surfaces prevent the buildup of dirt, bacteria, and other pollutants, ensuring that the space remains sterile.

The insulating core of the panels provides excellent thermal insulation, reducing the need for extensive heating or cooling systems. This energy-efficient feature helps maintain a stable temperature inside the clean room, which is crucial for sensitive processes, and also helps to lower operational costs.

The modular design of sandwich panels makes them easy to install and replace. Their pre-fabricated nature ensures faster construction times compared to traditional building materials, making them ideal for projects with tight deadlines.

The combination of energy efficiency, quick installation, and low maintenance costs makes clean room sandwich panels a cost-effective solution for creating controlled environments. Their long lifespan and minimal need for upkeep further enhance their value.

Clean rooms are subject to strict regulations regarding air quality, temperature, humidity, and cleanliness. Sandwich panels are designed to meet these standards, helping facilities achieve compliance with industry regulations and certifications, such as ISO 14644.

Clean rooms in pharmaceutical manufacturing and packaging facilities require stringent control over contaminants to ensure product safety. Clean room sandwich panels are used to construct the walls and ceilings of these spaces, preventing contamination during production.

In electronics manufacturing, even minute particles can cause defects in circuit boards and microchips. Sandwich panels help maintain a contamination-free environment for the assembly of sensitive electronic components.

Laboratories that deal with sensitive biological samples or conduct high-level research rely on clean rooms to maintain sterile conditions. Clean room sandwich panels are essential in providing the necessary environment for research and development.

The food industry also benefits from clean room environments, especially in the processing and packaging of products. Clean room sandwich panels ensure that the facility maintains the highest standards of hygiene, preventing foodborne pathogens and contamination.

Clean rooms in medical device manufacturing facilities ensure that products meet strict sterilization and contamination-free standards. Sandwich panels contribute to creating an environment where the risk of contamination is minimized, ensuring the safety of medical devices.

While clean room sandwich panels offer significant advantages, it’s important to consider their environmental impact. The production of sandwich panels involves the use of synthetic materials like polyurethane, which can contribute to environmental pollution. However, some manufacturers are now using more sustainable and eco-friendly materials for the core insulation, such as recycled materials or biodegradable options.

Additionally, the energy efficiency of these panels helps reduce overall energy consumption, contributing to the sustainability of the facility in the long run.

Clean room sandwich panels are an indispensable part of the modern industrial landscape. They offer an effective and efficient way to build controlled environments that are crucial for industries requiring strict cleanliness and temperature control. Their superior insulation, ease of installation, and low maintenance make them a popular choice for applications ranging from pharmaceutical manufacturing to electronics production. As industries continue to prioritize hygiene, safety, and efficiency, clean room sandwich panels will remain a key element in the design and construction of clean and controlled spaces.

Our new models offer superb design;competitive prices and their new features give them distinct advantages over similar products from other manufacturers.