The effectiveness of clean room sandwich panels at insu […]

The effectiveness of clean room sandwich panels at insulating against temperature and sound depends on several factors, including the materials used in their construction and the specific requirements of the clean room environment. Here's a breakdown:

Clean room sandwich panels typically use materials with high thermal insulation properties for their core, such as polyurethane (PU) foam, polyisocyanurate (PIR) foam, or mineral wool. These materials have low thermal conductivity, meaning they can effectively reduce heat transfer between the interior and exterior of the clean room. As a result, clean room sandwich panels can help maintain stable temperatures within the clean room environment, which is crucial for certain applications, such as pharmaceutical manufacturing or electronics assembly.

While clean room sandwich panels are primarily designed to provide thermal insulation, they can also offer some degree of sound insulation. The thickness and density of the core material, as well as the overall construction of the panel, can influence its soundproofing capabilities. However, it's important to note that clean room panels are not typically designed specifically for soundproofing purposes. Therefore, their effectiveness at reducing sound transmission may be limited compared to specialized soundproofing materials or construction techniques.

Clean room sandwich panels are generally effective at providing thermal insulation to help maintain stable temperatures within the clean room environment. While they can also offer some level of sound insulation, their primary function is to maintain cleanliness and controlled conditions rather than provide comprehensive soundproofing. For applications where sound insulation is a priority, additional measures may be necessary.

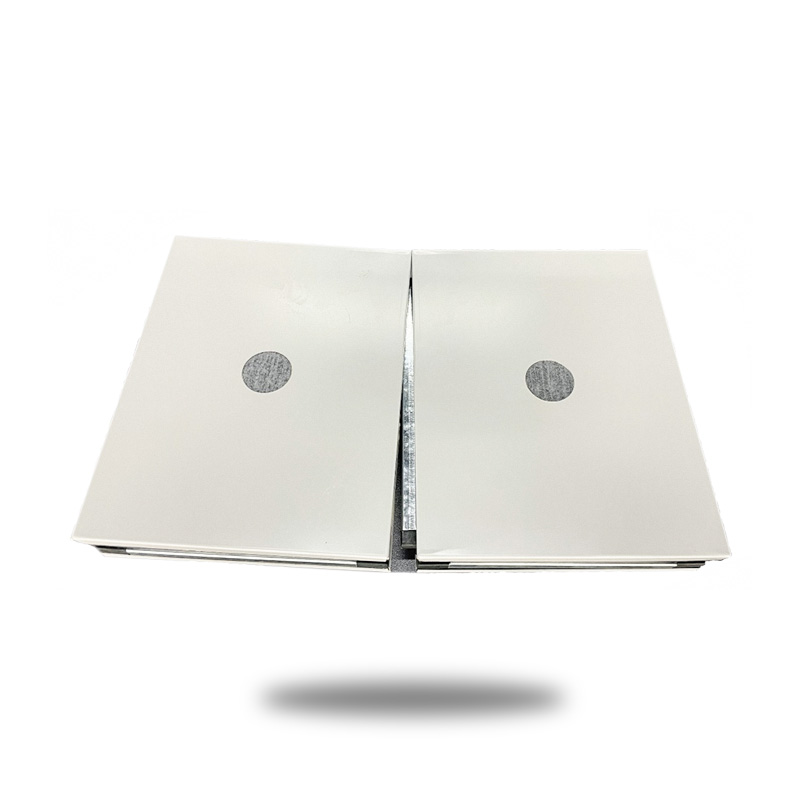

Our new models offer superb design;competitive prices and their new features give them distinct advantages over similar products from other manufacturers.