Clean room sandwich panels offer several advantages tha […]

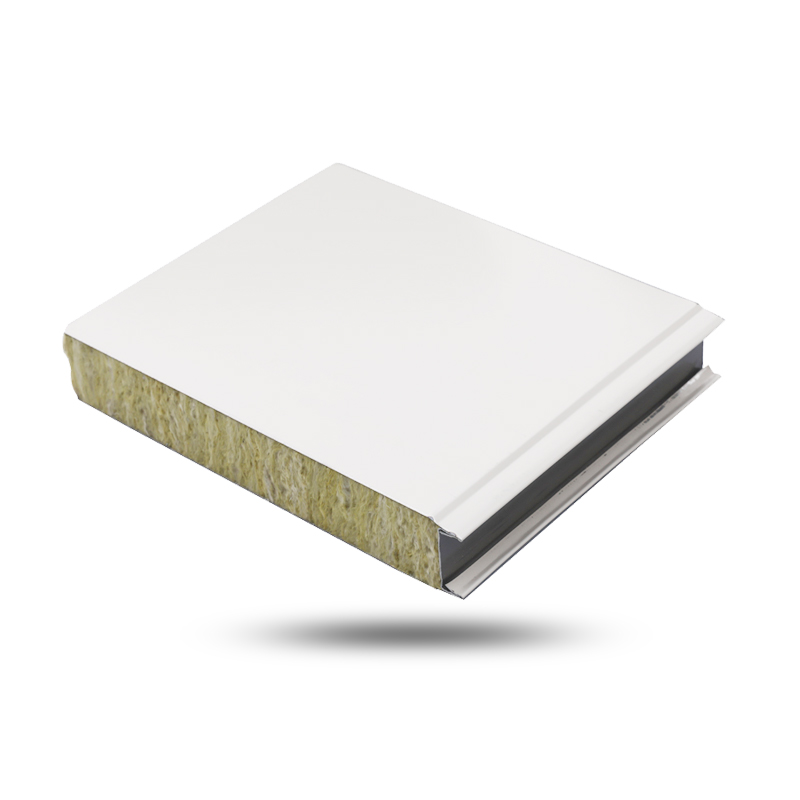

Clean room sandwich panels offer several advantages that make them suitable for creating controlled environments with low levels of dust, contaminants, and airborne particles. These advantages are highly beneficial in industries where cleanliness, precision, and environmental control are crucial. Here are some of the key advantages of clean room sandwich panels:

Contamination Control: Clean room panels are designed to maintain high levels of cleanliness. They effectively prevent the infiltration of dust, particles, and contaminants, ensuring the controlled environment remains free from impurities. This is essential in industries such as pharmaceuticals, electronics, and healthcare.

Temperature and Humidity Control: Clean room panels often provide thermal insulation, helping to regulate temperature and humidity within the controlled environment. This is important in industries where temperature and humidity control are critical, such as electronics manufacturing and food processing.

Energy Efficiency: The thermal insulation properties of clean room panels can contribute to energy efficiency by reducing the need for excessive heating or cooling. This can result in cost savings and a reduced environmental impact.

Soundproofing: Some clean room panels are designed to provide soundproofing, helping to control noise levels within the controlled environment. This is important in applications where noise-sensitive equipment or processes are involved.

Quick Installation: Clean room panels are often modular and relatively quick to install. This minimizes downtime during the construction or renovation of clean room facilities.

Customization: Clean room panels can be customized to meet specific requirements, including size, thickness, facing materials, and insulation properties. This flexibility allows them to be tailored to the needs of different industries and applications.

Fire Resistance: Clean room panels can incorporate fire-resistant materials, enhancing safety in environments where fire risk needs to be minimized.

Easy Maintenance: Regular maintenance and inspection of clean room panels are generally straightforward. Cleaning and repairing damaged panels can be done efficiently, ensuring the longevity of the controlled environment.

Longevity: High-quality clean room panels are durable and long-lasting, providing a reliable solution for maintaining controlled environments.

Compliance with Industry Standards: Clean room panels are designed to meet industry-specific standards and regulations, making them suitable for use in industries with stringent requirements.

Versatility: Clean room panels can be used in various industries, including pharmaceuticals, electronics, healthcare, aerospace, and food processing. They are adaptable to different applications and environments.

Environmental Considerations: Some clean room panels are designed to be environmentally friendly and may be recyclable or made from sustainable materials, contributing to sustainability efforts.

Easy Retrofits: Clean room panels can be used for retrofitting existing facilities, allowing the creation of controlled environments without the need for extensive construction or renovation.

These advantages make clean room sandwich panels a valuable choice for industries and applications where maintaining a clean, controlled, and stable environment is critical for product quality, safety, and research integrity. The specific benefits of clean room panels can vary depending on the type of panels chosen and the requirements of the controlled environment.

Our new models offer superb design;competitive prices and their new features give them distinct advantages over similar products from other manufacturers.