With the development of modern industry and technology, […]

With the development of modern industry and technology, cleanrooms are increasingly used in various fields, such as electronic manufacturing, pharmaceuticals, biotechnology, food processing and other industries. When building cleanrooms, cleanroom sandwich panels have become an indispensable and important material due to their excellent performance and diverse applications.

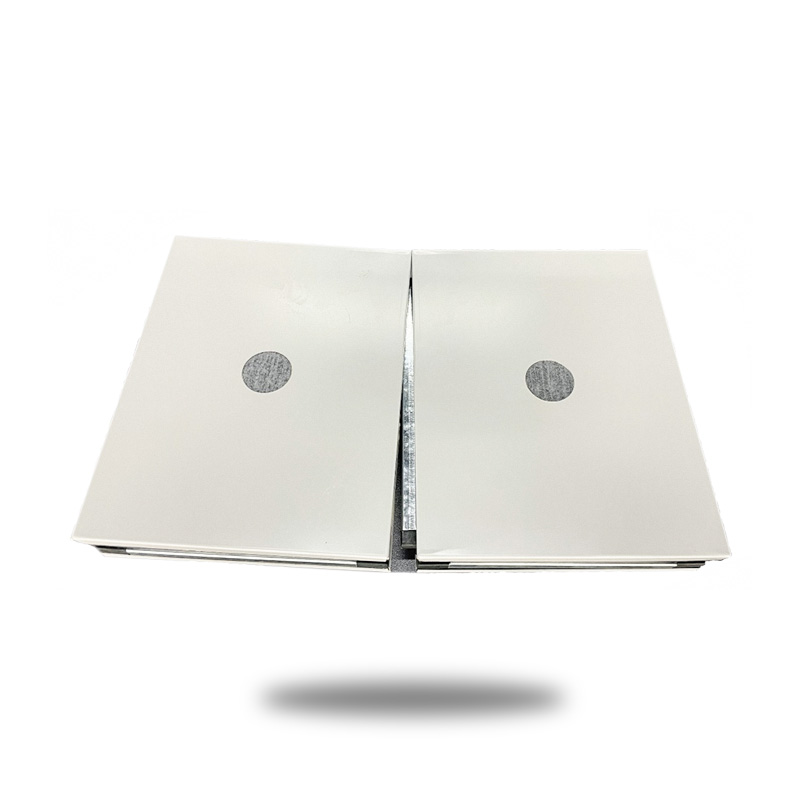

Cleanroom sandwich panels are a composite panel designed specifically for cleanroom environments, consisting of two layers of surface panels and a sandwich material in the middle. Common materials for surface panels include galvanized steel plates, stainless steel plates or aluminum alloy plates, while the sandwich materials may be polyurethane (PU), rock wool, polystyrene (EPS) or glass magnesium plates.

Its structural characteristics enable it to have good heat insulation, sound insulation, fire resistance and corrosion resistance while maintaining high strength, providing superior environmental protection for cleanrooms.

The surface of the cleanroom sandwich panel has been specially treated to be smooth and seamless, and is not easy to adhere to dust and microorganisms, meeting the strict cleaning requirements of cleanrooms.

Clean rooms have extremely high requirements for air quality and airflow control. The sealing of sandwich panels can effectively prevent external pollutants from entering and ensure the cleanliness level of the room.

Depending on the sandwich material, clean room sandwich panels can provide a certain fire protection level (such as Class A fireproof rock wool sandwich panels) to improve the safety of the clean room.

The thermal insulation characteristics of sandwich panels help to stabilize the temperature in the clean room and reduce energy consumption.

Clean room sandwich panels usually adopt modular design, which is easy to cut, install and disassemble, and can significantly shorten the construction period and improve efficiency.

In semiconductor and integrated circuit manufacturing, clean room sandwich panels are widely used in the construction of walls, ceilings and floors to ensure extremely high cleanliness levels.

Pharmaceutical production has particularly strict requirements on the sterility and cleanliness of the environment. Sandwich panels can not only provide a stable clean environment, but also withstand corrosive chemicals.

Food processing plants use clean room sandwich panels to build production spaces, which can effectively prevent microbial contamination and ensure food safety.

In medical equipment manufacturing, there is strict control over the cleanliness of the environment. The use of sandwich panels can ensure compliance with ISO 14644 clean room standards.

In recent years, with the continuous growth of global cleanroom demand, the market for cleanroom sandwich panels has also shown a trend of rapid expansion. Some technological innovations have further improved its performance and applicability:

With the promotion of the concept of green building, more environmentally friendly sandwich materials such as honeycomb panels and glass magnesium panels have received attention to reduce the impact on the environment.

The development of smart cleanrooms has promoted the intelligent design of sandwich panels, such as embedded sensors or smart coatings to achieve real-time monitoring of temperature, humidity and cleanliness.

Some sandwich panel products integrate lighting, ventilation and electrical wiring functions to further optimize the overall layout and functionality of the cleanroom.

Select appropriate sandwich materials according to the specific application areas and fire protection level requirements of the cleanroom.

Ensure that the thickness and strength of the board meet the load-bearing requirements of the cleanroom structure, especially the wall and ceiling parts.

High-quality sandwich panels should have stable performance for long-term use to avoid affecting the air tightness of the cleanroom due to aging or deformation.

Cleanroom sandwich panels provide reliable guarantee for the construction of modern industrial cleanrooms with their excellent performance, flexible application and cost-effectiveness. In the future development, with the improvement of environmental protection and intelligent demand, this material will continue to evolve and bring more possibilities to the field of clean technology.

Whether driven by technological innovation or industry demand, clean room sandwich panels will continue to play an irreplaceable and important role and contribute to the realization of high-standard clean environment.

Our new models offer superb design;competitive prices and their new features give them distinct advantages over similar products from other manufacturers.