The Advantages of a Clean Room Rock Wool Panel When it […]

The Advantages of a Clean Room Rock Wool Panel

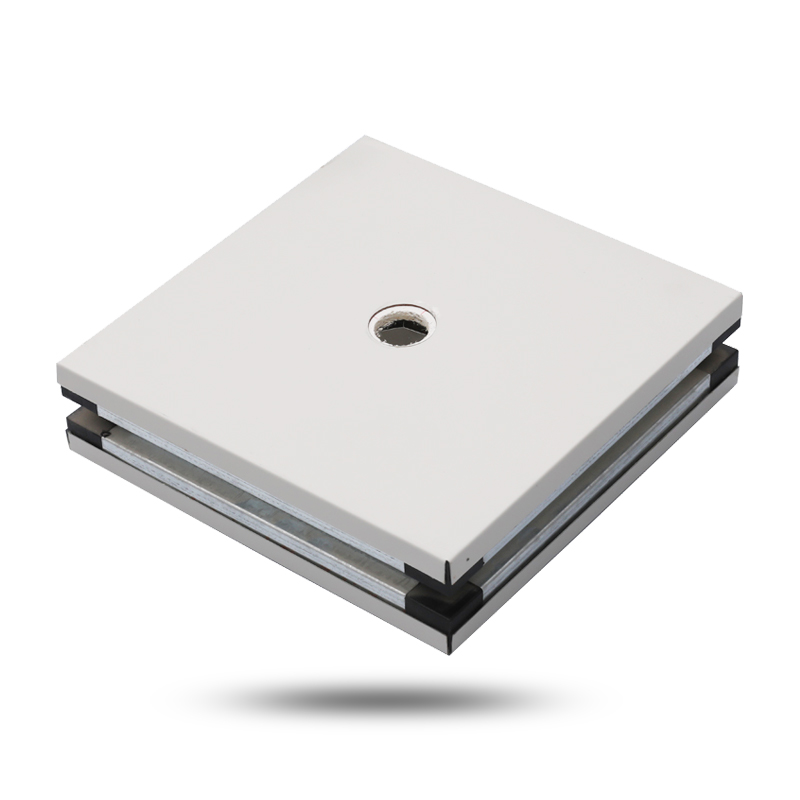

When it comes to selecting the right material for your construction, there are several factors to take into account. These include cost, resistance, compressibility, and environmental impact. Knowing these details is crucial to a successful project. For example, a clean room rock wool panel is one of the most efficient and effective acoustic insulations available for the construction industry.

Rockwool is a highly-durable inorganic fiber board that offers multiple advantages. It has excellent sound absorption capabilities, chemical stability, and fire resistance. Additionally, it is naturally stable. The K-value is 0.035 and its volume moisture absorption rate is less than 2%. This makes it an ideal insulating material for both clean rooms and weighing rooms.

In addition to providing excellent acoustic and thermal insulation, rock wool sandwich panels are also very fast and easy to install on the construction site. They are suitable for use in both residential houses and commercial buildings.

Rockwool cleanroom panels are a durable, non-combustible insulation material. They have a high density and are 4 to 5 times stronger than an ordinary rock wool strip. They are manufactured by the world's first clean board automatic production line, which saves time and increases production efficiency.

The production process of rockwool cleanroom panels involves a number of steps that combine specialized adhesives and hydraulic units. The production process ensures strong adhesion between the body and the inner wall. With its unique design and flatness, the cleanroom panel greatly improves product quality and stability.

Cleanroom rock wool panels are widely used in a number of applications, including industrial steel buildings, cleanrooms, and industrial facilities. They are particularly effective in reducing noise and creating a stable temperature year round. They are also useful in air clean rooms, refrigerators, and concert halls.

A clean room rock wool panel is a great choice for a sound-insulating material, because the insulation has a high density. It is ideal for construction projects with high requirements in fire prevention and sound-insulation.

The clean room rock wool panel can be customised with different materials. You can choose from AL honeycomb, PU, Magnesium, and XPS. However, you need to be careful about the rules in your country. If you are considering this type of wall panel, you need to know the regulations and requirements in your country.

Another important factor to consider when choosing the best insulation is the thickness. In the case of a modular sandwich panel, the thickness will influence the insulation properties. One of the advantages of the rockwool cleanroom panel is that it is a natural, stable material that does not change with changes in humidity.

Rockwool cleanroom panel is a perfect choice for large industrial buildings such as factories. It also provides a variety of benefits, such as low water absorption and low thermal conductivity. Also, it is able to provide insulation for a variety of holes and pipeline boxes.

Whether you are looking for a cleanroom rock wool panel, a weighing room panel, or an aluminum sandwich panel, there are many options for you. By understanding the different construction and maintenance processes, you can make an informed decision about which insulation material is best suited for your project.

MGO Modular Panel is an eco-friendly fire-proof panel with super fireproof performance, no dust accumulation and self clean function. The surface material is anti-stabak and easy to be cleaned. MGO Modular Panel can be used as roof/wall panel, ceiling panel, wall panel, flooring, furniture backside panel, acoustical lining board for any type of building structure such as home furnishings, office building/classroom decoration.

Our new models offer superb design;competitive prices and their new features give them distinct advantages over similar products from other manufacturers.