The construction and design of a clean room is one of t […]

The construction and design of a clean room is one of the most crucial stages of the project due to its significance for manufacturing processes. It is essential to select the correct materials and elements for this environment to ensure a long-term safety and quality standard that meets the requirements of users, while also ensuring optimum costs.

It is important to consider a variety of different factors when selecting the material for your clean room including cost, layout and ergonomics, safety and fire regulations and energy consumption. Additionally, the building's location and the type of operations carried out there will also have an influence on the selection of materials.

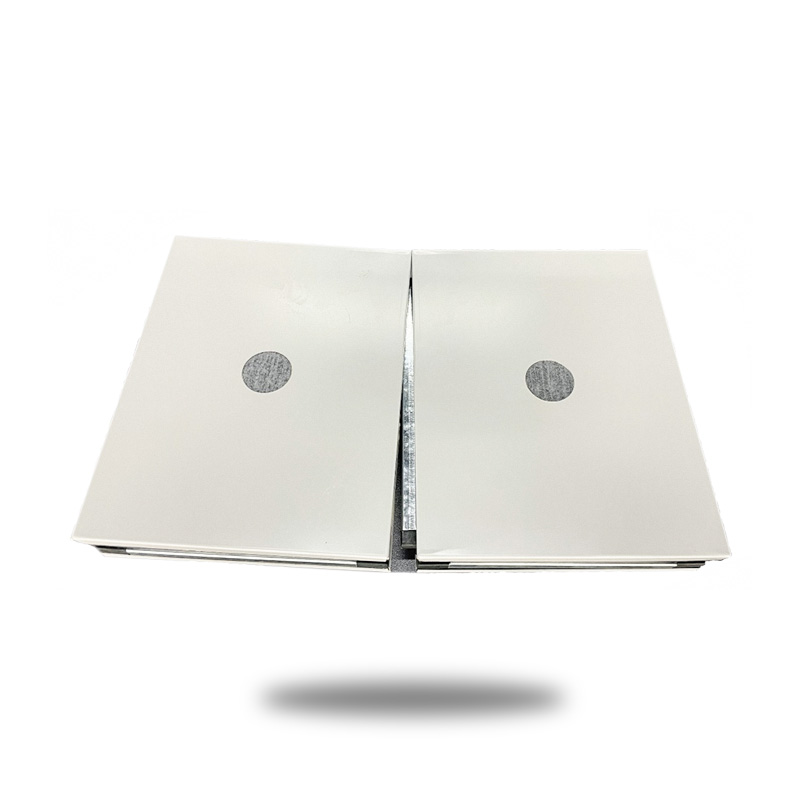

In order to achieve the highest levels of cleanliness, the use of insulated sandwich panels is a sound choice for clean rooms. These panels have excellent thermal insulation properties and provide acoustic insulation, as well as high fire resistance.

They are lightweight and can be assembled easily, which is a great advantage for erecting clean rooms in existing buildings. They are also non-hygroscopic and prevent the spread of fungi, mold and other contaminants.

The insulated sandwich panels are manufactured on a continuous line and as ready to assemble pieces in the dimensions, insulation types and colors required for your facility. Engineering and quality control processes are carried out at the factory before being shipped to the project site, reducing the cost of shipping, transportation, installation and labor expenditures considerably.

These panels are available in different widths, heights and thicknesses to meet all your cleanroom needs. Depending on the application and size of your cleanroom, the panel's insulation core can be made of PUR, polyisocyanurate foam (PIR) or mineral wool.

It can be manufactured in any color and is available with a variety of finishes, including an epoxy coating. Its high-temperature resistance makes it ideal for the production of medical devices and pharmaceutical products.

In addition to these benefits, the insulated sandwich panel has a range of other features that can be useful in a clean room. It is easy to disinfect and can be sanitized even with varying chemical pH levels.

Stainless steel is an excellent option for clean rooms because it offers strong corrosion resistance to cope up with a wide variety of chemicals, such as the fumes from various substances that are produced during the manufacturing process. It is also resistant to chlorine and chloride ions, making it highly effective against corrosive substances.

This is especially beneficial in the case of chemical cleaning. Stainless steel sandwich panels are also highly resistant to dust, germs and microorganisms.

The insulated sandwich panels are widely used for clean rooms and have a wide range of applications in the production sector, ranging from food, electronics to medical and biological equipment. They are particularly suitable for manufacturing and production environments that require strict standards of cleanliness.

Our new models offer superb design;competitive prices and their new features give them distinct advantages over similar products from other manufacturers.