The installation and maintenance of clean room panels a […]

The installation and maintenance of clean room panels are critical for ensuring the continued effectiveness of the controlled environment and adherence to cleanliness standards. Proper installation and regular maintenance contribute to preventing contamination, optimizing energy efficiency, and extending the lifespan of the clean room. Here are the installation and maintenance requirements for clean room panels:

Installation Requirements:Qualified Installation Team: Clean room panels should be installed by a team of professionals experienced in clean room construction and panel installation to ensure proper handling, alignment, and sealing.

Site Preparation: The installation site must be thoroughly cleaned and prepared to minimize the introduction of contaminants. Any necessary structural modifications should be completed before panel installation.

Panel Handling: Clean room panels should be handled with care to avoid scratching or damaging surfaces. Gloves and protective coverings should be worn during installation to prevent skin oils and particles from getting on the panels.

Sealing and Gaskets: Proper installation of gaskets and sealing systems is crucial to prevent air leakage between panels. All joints, corners, and connections should be carefully sealed to maintain the integrity of the controlled environment.

Airflow and Ventilation: The installation should consider airflow patterns and the placement of air returns, filters, and vents to ensure efficient air circulation and filtration within the clean room.

Integration of Services: Electrical wiring, lighting, HVAC systems, and any other services integrated into the clean room panels should be installed correctly and tested for functionality.

Alignment and Leveling: Clean room panels should be accurately aligned and leveled to create a seamless appearance and minimize potential gaps that could accumulate contaminants.

Window and Door Installation: If the clean room panels include windows or doors, their installation should be carried out meticulously to maintain proper sealing and prevent air leakage.

Maintenance Requirements:

Regular Inspections: Scheduled inspections should be conducted to identify any wear, damage, or deterioration in the clean room panels, gaskets, seals, and integrated systems.

Cleaning Procedures: Cleaning protocols should be established and followed regularly to remove dust, particles, and any potential contaminants from the clean room panels and surfaces. Only approved cleaning agents should be used to avoid chemical reactions.

Gasket and Seal Checks: The integrity of gaskets and seals should be checked to ensure they are still effective in maintaining air-tight connections between panels.Air Filters: If the clean room has air filtration systems, filters should be checked and replaced according to the manufacturer's recommendations to ensure proper air quality.

HVAC Maintenance: The heating, ventilation, and air conditioning systems should be regularly maintained to ensure proper airflow, temperature control, and filtration.Electrical and Lighting Maintenance: Electrical components and lighting fixtures integrated into the clean room panels should be inspected and maintained as needed.

Repairs and Replacements: Any damaged panels, gaskets, seals, or integrated components should be repaired or replaced promptly to prevent contamination risks and maintain the clean room's performance.

Documentation: Maintenance activities, repairs, and replacements should be well-documented to track the history of the clean room's condition and to ensure compliance with regulatory requirements.

By following these installation and maintenance requirements, organizations can uphold the cleanliness, efficiency, and functionality of their clean room panels and controlled environments over time. Regular monitoring and upkeep are essential for preventing

contamination issues and ensuring the longevity of the clean room's effectiveness.

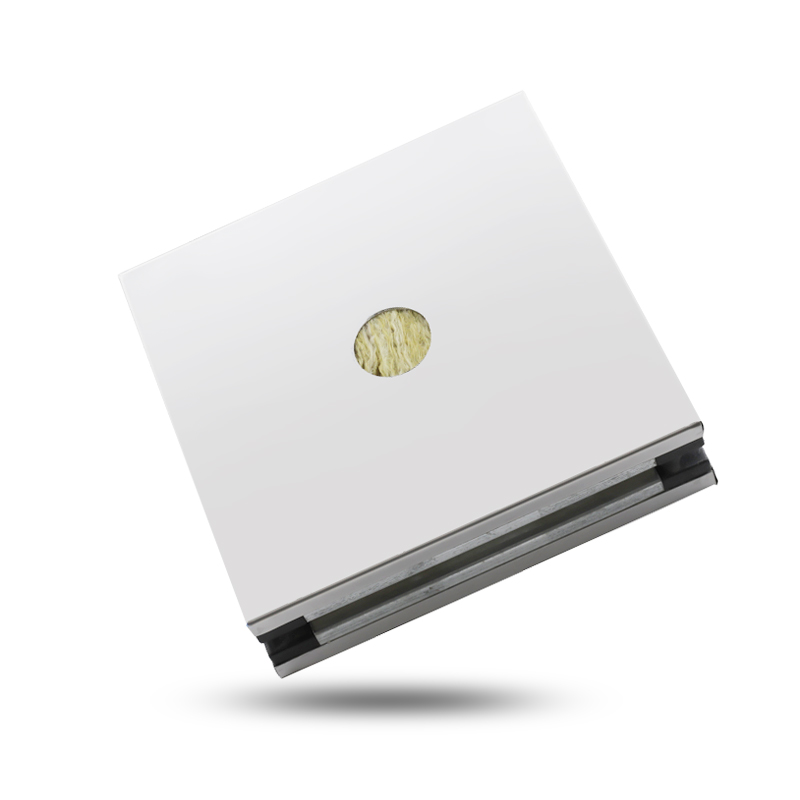

Our new models offer superb design;competitive prices and their new features give them distinct advantages over similar products from other manufacturers.