Clean room panels are utilized across various industrie […]

Clean room panels are utilized across various industries that require controlled environments with specific levels of cleanliness and contamination control. These industries rely on clean room panels to maintain the quality, safety, and integrity of their products, processes, and research. Some of the key industries that use clean room panels include:

Pharmaceuticals and Biotechnology: These industries require sterile and contamination-free environments to produce medications, vaccines, and biotechnological products. Clean room panels ensure the integrity of these sensitive processes.

Microelectronics and Semiconductor Manufacturing: The production of microchips, integrated circuits, and other electronic components demands environments with extremely low levels of airborne particles. Clean room panels are essential in preventing defects that could impact the functionality of electronic devices.

Medical Devices: Manufacturing medical devices such as implants, surgical instruments, and diagnostic equipment requires clean environments to prevent contamination that could compromise patient safety.

Aerospace and Defense: Aerospace companies utilize clean room panels to manufacture sensitive components like satellite parts and precision instruments, ensuring their performance in demanding conditions.

Optics and Photonics: Industries that produce optical and photonic devices, such as lasers, sensors, and imaging equipment, rely on clean room environments to achieve the necessary precision and performance.

Research and Development: In research facilities, clean room panels provide controlled spaces for experiments in various scientific fields, including physics, chemistry, materials science, and nanotechnology.

Food and Beverage: Some sectors of the food and beverage industry require clean environments for producing sterile or sensitive products, such as dairy products, beverages, and specialized foods.

Healthcare: Hospitals and medical facilities use clean room panels in areas like surgical suites, sterile compounding pharmacies, and research laboratories.

Biomedical and Life Sciences: Laboratories conducting research in genetics, cellular biology, and other life sciences benefit from clean room environments to maintain the purity of experiments and prevent cross-contamination.

Automotive: Clean room panels are used in the automotive industry for manufacturing precision components, such as engine parts, sensors, and electronics.

Precision Engineering: Industries involving high-precision machining, metrology, and tooling rely on clean room environments to ensure accurate measurements and manufacturing processes.

Textiles and Fabrics: Some textile industries require clean rooms to produce specialized fabrics used in clean room apparel, medical textiles, and other sensitive applications.

Art Conservation: In art restoration and conservation, clean room environments are used to protect valuable artworks during cleaning, repair, and analysis.

Energy and Environmental Sciences: Clean room panels support research and development in renewable energy technologies, energy storage, and environmental monitoring.

Nanotechnology: The field of nanotechnology often requires ultra-clean environments to manipulate and study materials at the nanoscale.

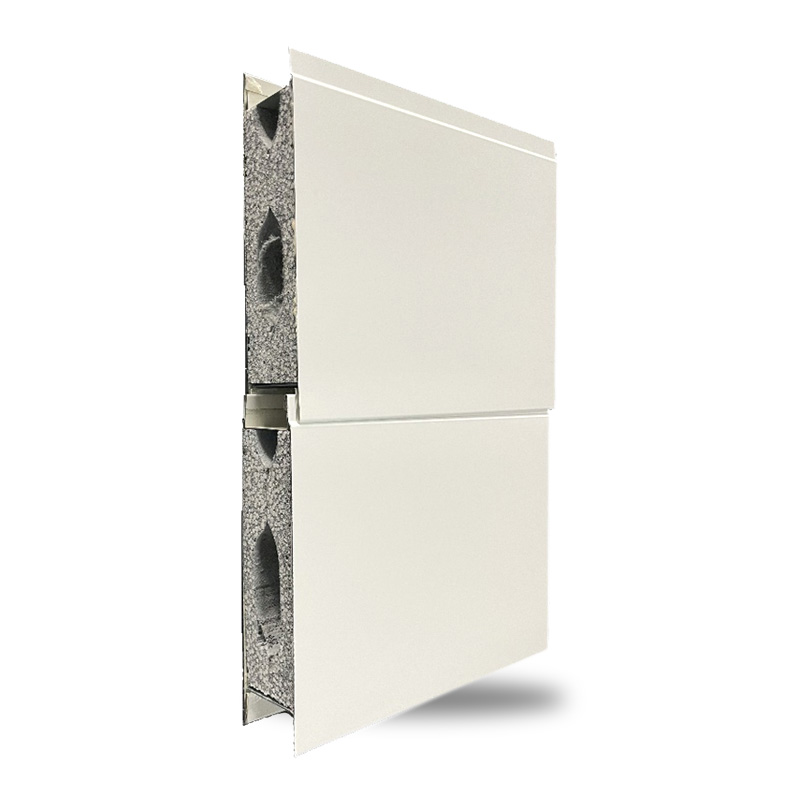

Clean room panels play a critical role in these industries by providing the controlled environments necessary for maintaining product quality, process integrity, and compliance with regulatory standards. The specific requirements and cleanliness levels vary from one industry to another, highlighting the versatility and adaptability of clean room panel technology.

Our new models offer superb design;competitive prices and their new features give them distinct advantages over similar products from other manufacturers.