Sandwich panels are composite materials consisting of t […]

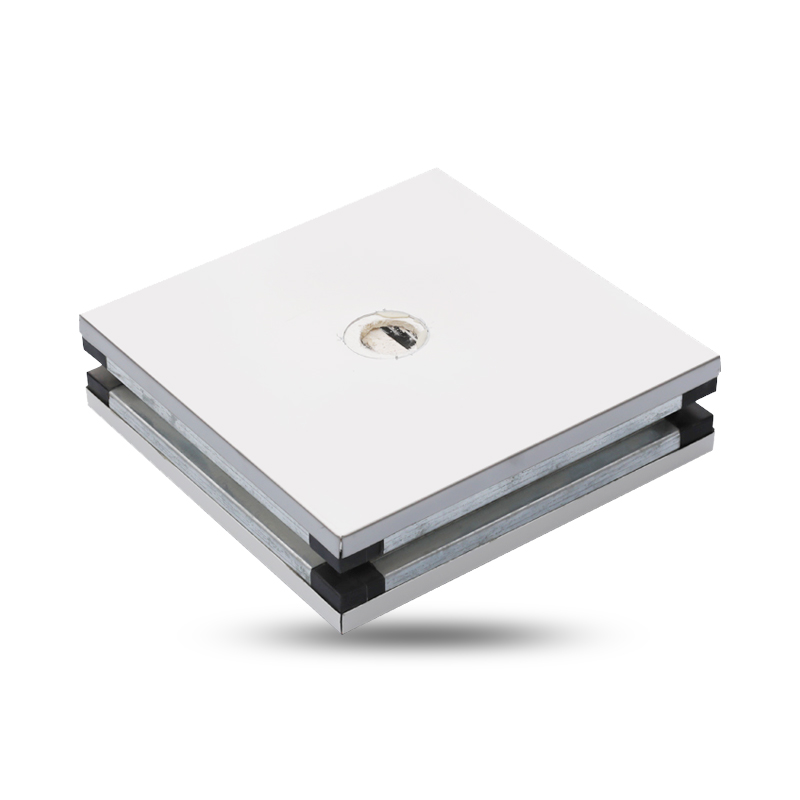

Sandwich panels are composite materials consisting of three main components: two face sheets (also known as skins or facings) and a core material. The combination of these components results in a structure that provides enhanced properties such as strength, insulation, and light weight. The materials typically used in the composition of sandwich panels include:

Face Sheets:

Metal Sheets: Common face sheet materials include metals such as aluminum or steel. These sheets provide durability, weather resistance, and a smooth outer surface.

Fiber-Reinforced Plastic (FRP): Fiberglass-reinforced plastic is another face sheet option, offering a lightweight and corrosion-resistant material suitable for certain applications.

Plywood or Wood: In some cases, plywood or wood-based materials may be used as face sheets, especially in applications where a natural or textured appearance is desired.

Core Material:

Polyurethane (PU): PU foam is a common core material known for its excellent insulation properties and lightweight nature. It is often used in applications where thermal efficiency is crucial.

Polyisocyanurate (PIR): PIR foam is similar to PU foam but offers improved fire resistance. It is suitable for applications where fire safety is a key consideration.

Expanded Polystyrene (EPS): EPS foam is a lightweight and cost-effective core material known for its insulation properties. It is commonly used in construction and packaging.

Mineral Wool: Mineral wool, made from basalt or rock fibers, provides good fire resistance and acoustic insulation. It is used in applications where fire safety and soundproofing are important.

Honeycomb Core: Honeycomb structures, often made of materials like aluminum or aramid fiber, offer high strength and stiffness with reduced weight. They are suitable for applications requiring lightweight yet strong panels.

Adhesive or Bonding Material:

Adhesive Layers: Adhesives or bonding materials are used to secure the face sheets to the core material. The choice of adhesive is critical for ensuring the structural integrity and longevity of the sandwich panel.

The specific combination of these materials depends on the intended application and the desired properties of the sandwich panel. Different industries, such as construction, aerospace, and transportation, may use sandwich panels with variations in face sheets, core materials, and adhesives to meet specific performance requirements. Additionally, manufacturers may offer customization options based on client preferences and project specifications.

Our new models offer superb design;competitive prices and their new features give them distinct advantages over similar products from other manufacturers.